TCM INDUSTRIE

We believe that without knowledge, there can be no talk of evolution. This is why we invest an important share of our turnover in research and development. With the markets as competitive as they are, the only way to share the leaders’ success is to improve the quality of organisational and production processes: this is our commitment to you and this is what you will find in your relationship with us.

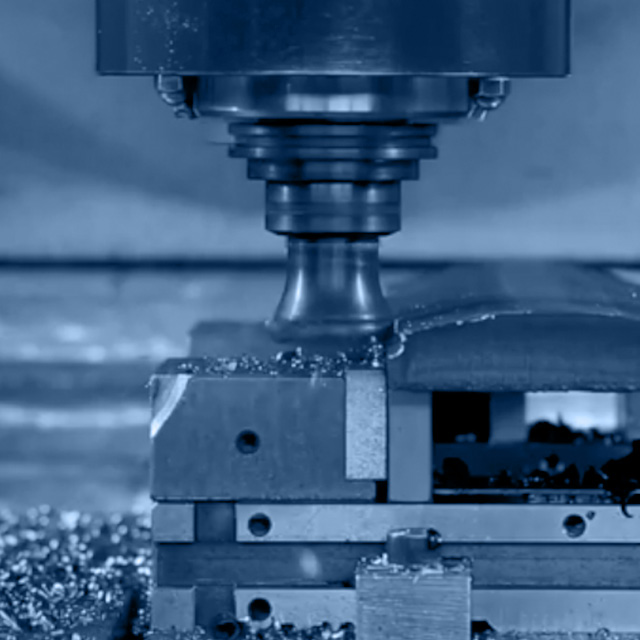

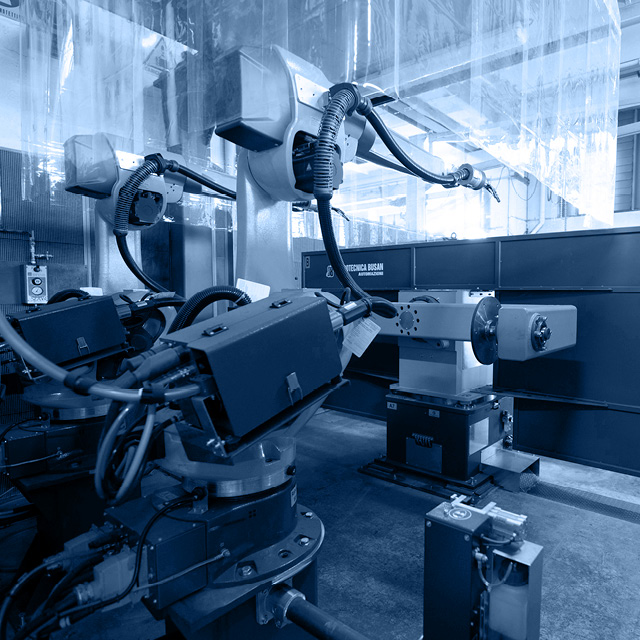

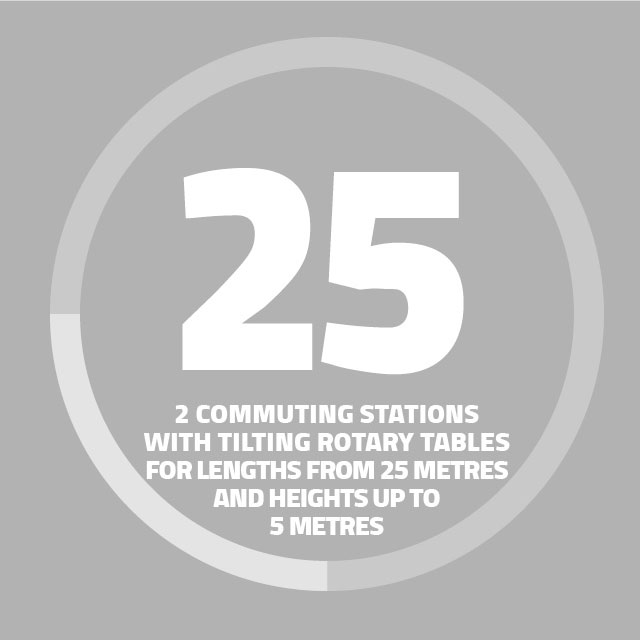

PROCESSES AND MACHINERY

TECHNOLOGY

“There can be no evolution without knowledge”, so our commitment to research and development is constant and continual, to offer you “total quality” every time.