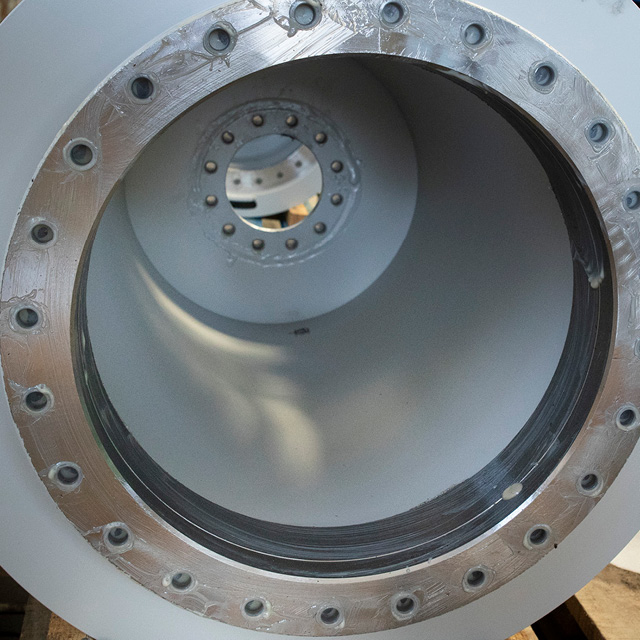

COMPONENT PRODUCTION

FOR ONSHORE AND OFFSHORE DRILLING SYSTEMS

Our drilling equipment is subjected to high levels of – often unforeseeable – stress due to the different morphological compositions of earth and soil. For this reason, TCM uses tested materials and specific equipment for this industry, complete with excellent resistance to wear and stress. Welds and chrome plating are all certified for heavy-duty work conditions. All component parts have certified high-resistance parameters (for components subject to stress) and optimised wear (for welds and chrome plating ).

TCM SYSTEM

Our work with you begins long before the finished product arrives at the end of its design cycle, through strategic, operational co-engineering.

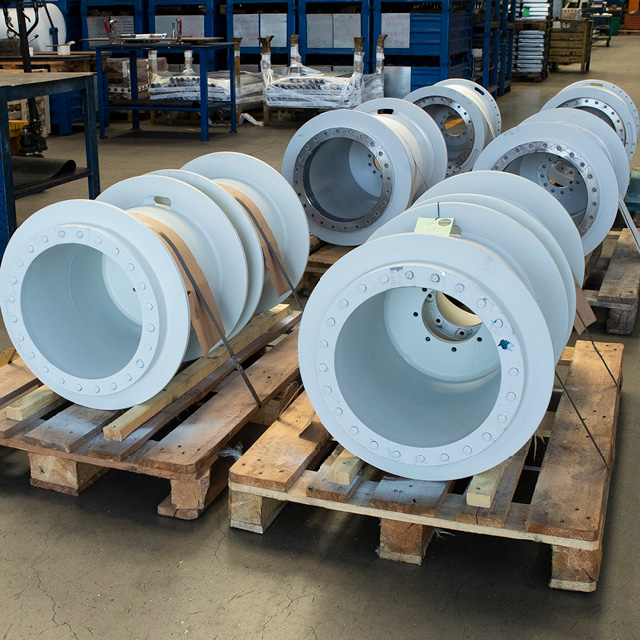

Our work centres and our high-tech, robotised systems are able to create complex products in small batches as well as on large scales.

We are often called on to manage complex production projects as prime contractors, which goes to show how we are able to achieve different types of processing and treatments, all of which we manage in-house.

Our logistics system allows us to have considerable storage capacity when it comes to finished products and raw materials, and this works to the benefit of smooth operations and compliance with delivery times

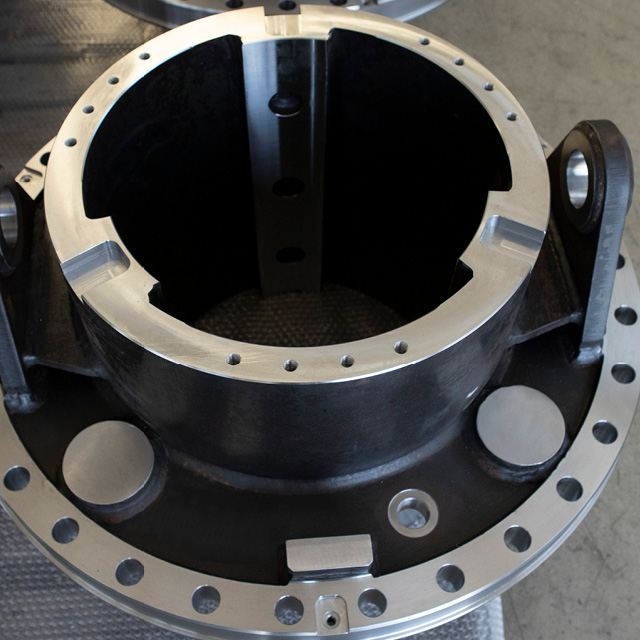

CERTIFIED FLOW CONTROL

Our system allows management of inbound and outbound customer data flows, with EDI protocol, certified by players of global importance, with impressive operating benefits.

Traceability of all production lots and all quality inspections guarantees control and repeatability.